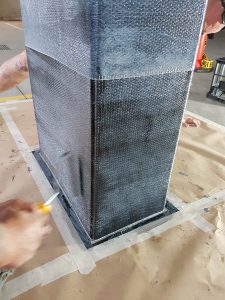

Carbon fibre has very high tensile strength and is also very lightweight. When bonded to the exterior of a concrete column, beam, or slab, it can add significant strength without adding weight that would increase the load on foundations and other structural members. The composite material is called fibre-reinforced plastic (FRP). FRP wraps are easy to apply and can be used on any size or shape of structural member. Traditional techniques for strengthening, such as adding concrete and reinforcing steel around the outside of a structural member, external post-tensioning, or adding structural steel supports often are more expensive due to the extra work to get everything into place.

Carbon fibre has very high tensile strength and is also very lightweight. When bonded to the exterior of a concrete column, beam, or slab, it can add significant strength without adding weight that would increase the load on foundations and other structural members. The composite material is called fibre-reinforced plastic (FRP). FRP wraps are easy to apply and can be used on any size or shape of structural member. Traditional techniques for strengthening, such as adding concrete and reinforcing steel around the outside of a structural member, external post-tensioning, or adding structural steel supports often are more expensive due to the extra work to get everything into place.

The primary reason to use this technique is to add strength to an existing structure. In some cases, it might be used on new construction. In appropriate applications, Carbon Fibre reinforced polymer strengthening can be 30% to 50% less expensive than traditional strengthening due to the ease of installation.

Carbon Fibre strengthening gaining in popularity is strengthening of concrete tanks, culverts, and prestressed concrete water pipes. The FRP layer not only strengthens the structure but provides an impermeable a layer of impervious materials to protect the structure from moisture intrusion and further corrosion.