Oct

Basalt fibre for concrete mix

- 2020

- admin

- To Write First

Basalt fibre for concrete mix study

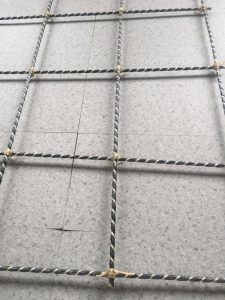

The shortcomings of plain concrete can be reduced by adding reinforcing bars or prestressing steel. Reinforcing steel is continuous and is specifically located in the structure

to increase performance. Fibres are discontinuous and are generally distributed randomly

throughout the concrete matrix. Randomly dispersed fibres provide a three-dimensional

reinforcement compared to the traditional rebar which provides two-dimensional

reinforcement. Fibre reinforced concrete can be a cost effective and useful construction

material because of the flexibility in methods of fabrication. In slabs on grade, mining,

tunneling, and excavation support applications, steel and synthetic fibre reinforced

concrete and shotcrete have been used in lieu of welded wire fabric reinforcement

One of the greatest benefits gained by using fibre reinforcement is improved long-term

serviceability of the structure or product if properly engineered. Serviceability is the ability

of the specific structure or part to maintain its strength, integrity, and to provide its designed

function over its intended service life. Fibres can prevent the occurrence of large cracks.

These cracks permit water and contaminants to enter causing corrosion of reinforcing steel.

In addition to crack control and serviceability benefits, use of fibres at high volume

percentages (5% to 10% or higher by volume) can substantially increase the tensile strength

of FRC .

Basalt fibres are manufactured in a single-stage process by melting crushed volcanic basalt

rock. They are environmentally safe, non-toxic, possess high heat stability, and insulating

characteristics, and have an elastic structure. Basalt fibres are extremely strong and durable

and hence, it is an ideal material for structural and other construction related applications.

It provides unique mechanical properties when used in composite materials. The

mechanical characteristics of roving depend on the diameter of the elemental fibres.

Elemental fibres with smaller diameter show higher tensile strength and modulus of

elasticity than those of elemental fibres with larger diameter.

Basalt filaments are made by melting crushed volcanic basalt rock . The molten material is then extruded through special platinum bushings to produce continuous filaments of basalt fibre. The three main manufacturing techniques of basalt filaments are centrifugal-blowing, centrifugal-multiroll, and dieblowing. The fibres cool into hexagonal chains resulting in a resilient structure

substantially stronger that steel or glass fibres. Its production creates no environmental

waste.

Basalt roving is a bundle of continuous mono-directional complex basalt fibres. Basalt fibre has electrical insulating properties 10 times better than glass and has better chemical resistance than glass fibre, especially in strong alkalis. It reduces the risk of environment pollution unlike glass fibre which produces high-toxic metals and oxides during its production. Furthermore, basalt fibre has higher stiffness and strength than glass fibre.

Chopped basalt fibres are made from a continuous roving using drum chopping machines Hence, the addition of basalt fibre does not increase the dead load of FRC compared to steel fibre.

Basalt fibres are corrosion resistant unlike steel fibres. In addition, basalt fibre also has

excellent temperature resistance anti-oxidation, and anti-radiation characteristics .

Following are some of the characteristics of basalt fibre:

– High tensile strength, high thermal conductivity, high modulus of elasticity, high

sound absorption, high friction, frost, heat, and moisture resistance

– Chemical resistance to acids/alkalis, and aggressive chemicals

– No carcinogenic risk or other health hazards

– Completely inert with no environmental risks (eco-friendly)

– Good fatigue resistance

– Electro-magnetic resistance

– Resistance to ultraviolet radiation

– Dielectric characteristics

– Light weight

Basalt fibre is an effective reinforcing additive component to concrete because it improves

the thermal and mechanical properties of concrete. Basalt fibre has good adhesion with the

cement matrix. The main factor for chemical stability of basalt fibre in concrete is the

presence of heavy metal oxides in its molecular structure (Al2O3 and Fe2O3), which

prevents disintegration of basalt fibres in a highly alkaline concrete environment.

Beyond Materials Group is a growing manufacturer of non–ferrous basalt fibre materials and can meet your specification and quality requirements for a wide variety of custom applications. From our head office in Gold Coast we are able to ship our basalt products Australia wide.

Gold Coast, Brisbane, Sydney, Adelaide, Melbourne, Perth.

The findings have shown that BFRP rebar is a stronger and lighter alternative to steel reinforcement in concrete beams, and that it is a very promising building material for the future. Furthermore, fewer material and energy resources are required during the production process, which leads to a better environmental profile with fewer embodied emissions. In contrast, the mechanical testing part of this experiment showed that the BFRP reinforcement has a lower elastic module than steel reinforcement. This disadvantage leads to excessive deformation at service limit state compared to steel bars, if the same cross-section area is used. However, compared to steel, BFRP does not exhibit yielding during tension. When the BFRP environmental results were compared to EPD data, there were two core findings. Firstly, EPDs for precast steel reinforced concrete beams have a similar amount of GWP emissions, ranging from 25.1 – 27.9 kgCO2eq/FU, compared to the steel reinforced concrete beams tested in this study, 23.7 kgCO2eq/FU. Secondly, when the EPD data for precast beams was replaced with EPD data for in-situ pouring concrete and 100% recycled steel, embodied emissions were significantly reduced to 11.3 kgCO2eq/FU. This result is competitive with the BFRP reinforced concrete beam that experiences 14.6 kgCO2eq/FU. These results highlight the environmental benefits to be

The findings have shown that BFRP rebar is a stronger and lighter alternative to steel reinforcement in concrete beams, and that it is a very promising building material for the future. Furthermore, fewer material and energy resources are required during the production process, which leads to a better environmental profile with fewer embodied emissions. In contrast, the mechanical testing part of this experiment showed that the BFRP reinforcement has a lower elastic module than steel reinforcement. This disadvantage leads to excessive deformation at service limit state compared to steel bars, if the same cross-section area is used. However, compared to steel, BFRP does not exhibit yielding during tension. When the BFRP environmental results were compared to EPD data, there were two core findings. Firstly, EPDs for precast steel reinforced concrete beams have a similar amount of GWP emissions, ranging from 25.1 – 27.9 kgCO2eq/FU, compared to the steel reinforced concrete beams tested in this study, 23.7 kgCO2eq/FU. Secondly, when the EPD data for precast beams was replaced with EPD data for in-situ pouring concrete and 100% recycled steel, embodied emissions were significantly reduced to 11.3 kgCO2eq/FU. This result is competitive with the BFRP reinforced concrete beam that experiences 14.6 kgCO2eq/FU. These results highlight the environmental benefits to be Another core finding was that both the BFRP tendons and reinforcement steel have similar emission factors: 2.6 and 2.34 kgCO2eq/kg respectively. However, since BFRP has a lower specific weight to steel, and is three times lighter, the overall embodied emissions are much lower in the BFRP reinforced concrete beams. This is because less material (per kg) is required to perform the same function. When considered without concrete, the LCA results showed the largest contributor to BFRP emissions was resin (86.8%). It was therefore ascertained that the LCA results are sensitive to the type and quantity of resin used, and that the amount of embodied emissions arising from resin are a significant driver of high emissions in BFRP tendons. This finding highlights an area for optimisation in the future. BFRP manufacturers could therefore experiment with the

Another core finding was that both the BFRP tendons and reinforcement steel have similar emission factors: 2.6 and 2.34 kgCO2eq/kg respectively. However, since BFRP has a lower specific weight to steel, and is three times lighter, the overall embodied emissions are much lower in the BFRP reinforced concrete beams. This is because less material (per kg) is required to perform the same function. When considered without concrete, the LCA results showed the largest contributor to BFRP emissions was resin (86.8%). It was therefore ascertained that the LCA results are sensitive to the type and quantity of resin used, and that the amount of embodied emissions arising from resin are a significant driver of high emissions in BFRP tendons. This finding highlights an area for optimisation in the future. BFRP manufacturers could therefore experiment with the