Oct

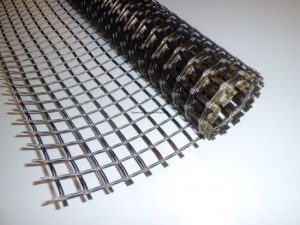

Basalt geogrid mesh

- 2017

- admin

- To Write First

Basalt reinforcing mesh with alkali resistant coating was developed to prevent cracks as well as for reinforcement of mortars and non load bearing concrete.

Basalt reinforcing mesh with alkali resistant coating was developed to prevent cracks as well as for reinforcement of mortars and non load bearing concrete.

The higher tensile strength of Basalt mesh, compared to E-glass or steel, increases impact resistance and prevents from cracks appearance. This mesh can meet the expectations and strict requirements of most demanding companies from construction market.

Our high-performance, alkali-resistant basalt mesh will not rot, rust or corrode, and it provides increased strength in different cementitious applications. Thanks to its lightweight, easy install and cut in size with a scissors.

Advantages and benefits:

- Specially developed coating provides good adhesion with concrete to improve tensile strength and increase impact resistance.

- High mechanical strength and modulus.

- High resistance to chemical aggressive environment and in particular high alkali resistance won’t allow appearance of rust or corrode.

- Minimizes crack width and spread

- Easy to install and use. No special equipment is required.

- Extremely low coefficient of heat conductivity significantly reduces heat transfer from building exteriors to interiors and significantly improves energy efficiency.

- Much higher electrical resistance compared to steel.

Beyond Materials Group is able to supply high quality basalt mesh and basalt geogrid mesh in full rolls and cut in size. From our head office in Gold Coast we are able to ship our products Australia wide.

Gold Coast, Brisbane, Sydney, Melbourne, Perth.