Basalt Rebar

Beyond Materials Group offers a wide range of non corrosive basalt materials used in concrete reinforcement, construction and manufacturing. Our non–ferrous reinforcement, Basalt reinforcement rebars and Geogrid mesh have been widely used in production of lightweight concrete panels and marine construction.

Basalt Rebar is an alternative to steel and fiberglass for concrete reinforcement.

Basalt fiber is a high performance non-metallic fiber made from basalt rock melted at high temperature.

Key Benefits of Basalt rebar:

- High strength and low weight

- High corrosion resistance

- High tensile modulus

- Non-conductive and non magnetic

- Easy installation

- Non–ferrous reinforcement,

Basalt rebar has much higher tensile strength than steel or fiberglass rebar of the same diameter.

Being 8-10 times lighter than steel, Basalt rebar is much easier to install.

Corrosion Resistance

Basalt does not rust or absorb water, so the depth of concrete cover can be reduced, allowing for thinner sections and more flexibility of design.

Basalt rebar is perfect for pervious concrete or applications where concrete is exposed to marine environments or areas affected by road salt. Basalt is naturally resistant to alkalis and will not act as a conduit for moisture.

Tensile Modulus

Tensile Modulus

Since Basalt is so strong in tension and compression, it cannot be bent or formed like steel. If tensile modulus issues arise, modifying the Basalt rebar adding more basalt in finer diameters in tighter grids closer to the surface will overcome any tensile modulus issues. Basalt rebar has the same thermal coefficient of expansion as concrete.

Basalt rebar is easily cut to length with regular tools.

Basalt rebar does not conduct electricity or induce fields when exposed to RF energy, great for MRI or data buildings.

Basalt rebar is perfect for Marine environments and Chemical plants where corrosion is a continuous concern.

Basalt Rebar is available in the following diameters: 4mm. 6mm. 8mm. 10mm. 12mm or customized.

• Stronger than steel wire of comparable size

• By far lighter and easier to handle and install (no nasty cuts).

• Will not rust or corrode or cause cracking of concrete

• Flexible for easier design

• Basalt does not conduct electricity or induce electric fields

• Basalt Mesh binds well with both asphalt and concrete

• Customize mesh sizes available 4-40mm

Basalt Fiber Geo-Grid Mesh

Used for reinforcing asphalt-concrete (covering in construction, reconstruction and repair of airport, runways, highways and any pavements, pedestrian ways, road inclines and banks).

Used for reinforcing asphalt-concrete (covering in construction, reconstruction and repair of airport, runways, highways and any pavements, pedestrian ways, road inclines and banks).

The reinforcement with basalt mesh Geo-grid increases the overall reliability, safety and the cutting process output. The strength of basalt mesh is as good as metal reinforcement, however it is lighter, thereby simplifying transportation and handling in construction.

Basalt Geo-grid Mesh is more durable than metallic and glass-fiber reinforcement due to basalt fiber’s excellent performance. Like all the basalt articles it is an ecologically safe material.

Basalt Chopped Fibres can be mixed directly into polymers and concrete to increase tensile strength and reduce cracking and chipping. ( Chopped Carbon Fibres are also available)

Basalt Chopped Fibres can be mixed directly into polymers and concrete to increase tensile strength and reduce cracking and chipping. ( Chopped Carbon Fibres are also available)

Basalt Chopped Fibres – Features & Benefits

• High tensile strength

• High tensile strength

• Resistant to alkali in concrete and require no special coatings

• Resist cold down to -260°F and heat up to 1,500°F

• Do not conduct electricity or induce electrical fields

• Do not absorb or wick water

• Will not harbor bacteria or microbial growth

• Has good fatigue resistance

Beyond Materials Group is a growing manufacturer of non–ferrous basalt fibre materials and can meet your specification and quality requirements for a wide variety of custom applications. From our head office in Gold Coast we are able to ship our basalt products Australia wide. BFRP

Gold Coast, Brisbane, Sydney, Adelaide, Melbourne, Perth.

Tensile Modulus

Tensile Modulus

Used for reinforcing asphalt-concrete (covering in construction, reconstruction and repair of airport, runways, highways and any pavements, pedestrian ways, road inclines and banks).

Used for reinforcing asphalt-concrete (covering in construction, reconstruction and repair of airport, runways, highways and any pavements, pedestrian ways, road inclines and banks).

• High tensile strength

• High tensile strength

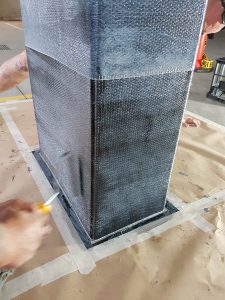

Carbon fibre has very high tensile strength and is also very lightweight. When bonded to the exterior of a concrete column, beam, or slab, it can add significant strength without adding weight that would increase the load on foundations and other structural members. The composite material is called fibre-reinforced plastic (FRP). FRP wraps are easy to apply and can be used on any size or shape of structural member. Traditional techniques for strengthening, such as adding concrete and reinforcing steel around the outside of a structural member, external post-tensioning, or adding structural steel supports often are more expensive due to the extra work to get everything into place.

Carbon fibre has very high tensile strength and is also very lightweight. When bonded to the exterior of a concrete column, beam, or slab, it can add significant strength without adding weight that would increase the load on foundations and other structural members. The composite material is called fibre-reinforced plastic (FRP). FRP wraps are easy to apply and can be used on any size or shape of structural member. Traditional techniques for strengthening, such as adding concrete and reinforcing steel around the outside of a structural member, external post-tensioning, or adding structural steel supports often are more expensive due to the extra work to get everything into place.